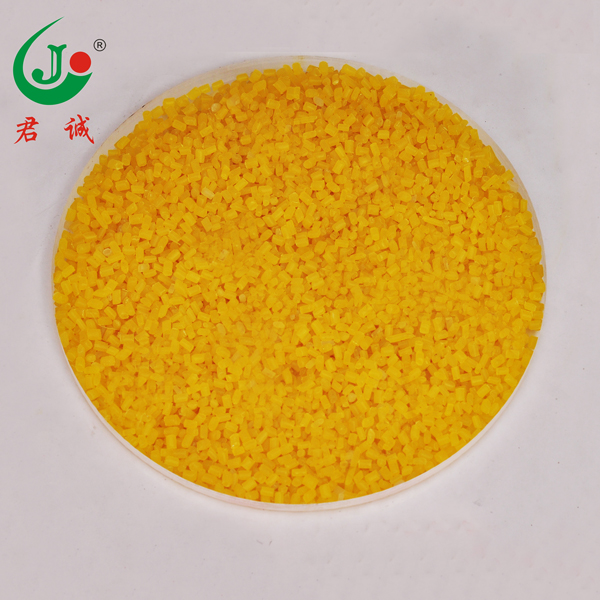

PA6 polyamide 6 or nylon 6 Typical applications

Due to the good mechanical strength and stiffness are widely used in structural parts. Because of good wear characteristics, but also for the manufacture of bearings.

Injection molding process conditions:

Drying: PA6 is very easy to absorb moisture, so the drying process before processing to pay special attention. If the material is supplied in watertight packaging, the container shall be kept closed. If the humidity is greater than 0.2%, it is recommended to dry for 16 hours in hot air above 80 ° C. If the material has been exposed to air for more than 8 hours, it is recommended to vacuum dry for more than 8 hours at 105 ° C.

Melting temperature: 230 ~ 280C, for the enhanced varieties of 250 ~ 280C.

Mold temperature: 80 ~ 90C. The mold temperature significantly affects the crystallinity, which in turn affects the mechanical properties of the plastic part. Crystallinity is important for structural parts, so a mold temperature of 80 to 90 ° C is recommended. For thin-walled, long-running parts, a higher mold temperature is also recommended. Increasing the mold temperature increases the strength and stiffness of the part, but reduces the toughness. If the wall thickness is greater than 3mm, it is recommended to use 20 ~ 40C low-temperature mold. For glass reinforcements, the mold temperature should be greater than 80 ° C.

Injection pressure: generally between 750 ~ 1250bar (depending on material and product design).

Injection speed: high speed (slightly reduced for reinforced materials). Runner and gate:

Because the setting time of PA6 is very short, the position of the gate is very important. Gate diameter not less than 0.5 * t (where t is the plastic thickness). If a hot runner is used, the gate size should be smaller than with a conventional runner because the hot runner can help prevent material from prematurely solidifying.

If a submerged entry gate is used, the minimum diameter of the gate shall be 0.75 mm.

Chemical and physical properties: PA6 chemical and physical properties and PA66 is very similar, however, its low melting point, and the process temperature range is very wide. Its impact resistance and anti-solubility better than the PA66, but the hygroscopicity is also stronger. Because many of the quality characteristics of plastic parts are subject to the impact of moisture absorption, the use of PA6 design products to take full account of this. In order to improve the mechanical properties of PA6, a variety of modifiers are often added.

Glass is the most common additive, sometimes in order to improve the impact resistance is also added synthetic rubber, such as EPDM and SBR and so on. For products without additives, the shrinkage of PA6 is between 1% and 1.5%.

Glass fiber additives can reduce shrinkage to 0.3% (but slightly higher in the direction perpendicular to the flow). Shrinkage of the molding assembly is mainly affected by the material crystallinity and moisture absorption. The actual shrinkage is also a function of the plastic part design, wall thickness and other process parameters